The Anchor Ace Hardware Store in Sandwich, Cape Cod, Massachusetts is now stocking the Farrow & Ball line of paint and wallpaper, and needed a display in keeping with F&B’s presentation in England and the U.S.. This was accomplished in Sandwich by dressing the store’s steel shelving with wood to give it the look of cabinetry while retaining the load capacity and modular characteristics of the system already in use.

I already had some experience in skinning steel shelves for the F&B display in Nantucket’s Marine Home Center, but the bones of this one differed significantly, requiring that I anticipate structure and fit without being able to assemble parts to test. My only instructions were to use F&B’s “Railings” for the Color Wall (or Colour Wall) and “Elephant’s Breath” for everything else, to fashion some kind of separation between the stock and the Color Wall and to be sure to fit the Color Wall in the middle. I decided that the best way to emulate a cabinet was to create a fascia along the top. There was no other opportunity to add much in the way of trim. Hopes of adding stiles or fluted pilasters went away with the realization that there was no vertical space between sections and that cans or promotional materials would be partially hidden and hard to handle behind anything added to the face.

I already had some experience in skinning steel shelves for the F&B display in Nantucket’s Marine Home Center, but the bones of this one differed significantly, requiring that I anticipate structure and fit without being able to assemble parts to test. My only instructions were to use F&B’s “Railings” for the Color Wall (or Colour Wall) and “Elephant’s Breath” for everything else, to fashion some kind of separation between the stock and the Color Wall and to be sure to fit the Color Wall in the middle. I decided that the best way to emulate a cabinet was to create a fascia along the top. There was no other opportunity to add much in the way of trim. Hopes of adding stiles or fluted pilasters went away with the realization that there was no vertical space between sections and that cans or promotional materials would be partially hidden and hard to handle behind anything added to the face.

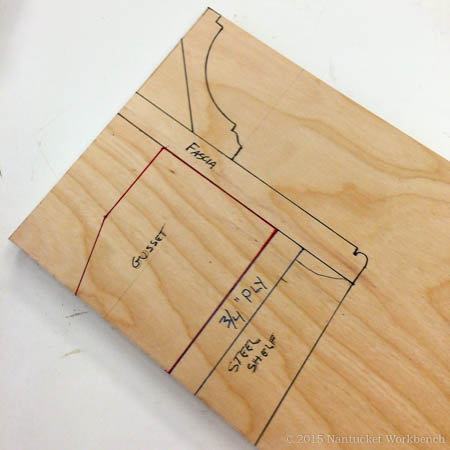

My first step was to draw a profile of a fascia and its support at full scale to see how it might work. A few pens of different colors, a piece of crown molding to trace and a scrap of plywood put me in business. As most of the height of the fascia would be above the ¾” plywood deck that was to mount on the steel, I added gussets to keep it plumb and secure. It seemed like a good idea to pull the fascia of the center section forward to help emphasize the Color Wall. At first I thought I would just add the crown to the center, but later decided to extend it out to each end.

My first step was to draw a profile of a fascia and its support at full scale to see how it might work. A few pens of different colors, a piece of crown molding to trace and a scrap of plywood put me in business. As most of the height of the fascia would be above the ¾” plywood deck that was to mount on the steel, I added gussets to keep it plumb and secure. It seemed like a good idea to pull the fascia of the center section forward to help emphasize the Color Wall. At first I thought I would just add the crown to the center, but later decided to extend it out to each end.

The fascia is made from a poplar 1×8 with a 5/16″ bead milled into the bottom edge. It’s attached to the deck with biscuits for location and pocket screws for fastening. It stops flush with one end where it meets another display and returns on the other where it passes over an end cap.

The fascia is made from a poplar 1×8 with a 5/16″ bead milled into the bottom edge. It’s attached to the deck with biscuits for location and pocket screws for fastening. It stops flush with one end where it meets another display and returns on the other where it passes over an end cap.

The molding is Eel Point Crown from Marine Home Center‘s Signature Design Series. A scrap of poplar board was attached to each end to protect the crown while other sections were built. Things get moved so many times in a small shop that the danger of banged-up corners is always present.

The molding is Eel Point Crown from Marine Home Center‘s Signature Design Series. A scrap of poplar board was attached to each end to protect the crown while other sections were built. Things get moved so many times in a small shop that the danger of banged-up corners is always present.

The stock shelves were covered by ¾” veneer core birch plywood with a beaded poplar edge band big enough to hide the metal. The edge band was biscuited, glued and well clamped before sanding and painting.

The stock shelves were covered by ¾” veneer core birch plywood with a beaded poplar edge band big enough to hide the metal. The edge band was biscuited, glued and well clamped before sanding and painting.

The skins were attached by driving ½” self-tapping screws through the steel with Milwaukee’s M18™ Fuel™ Impact Driver.

The skins were attached by driving ½” self-tapping screws through the steel with Milwaukee’s M18™ Fuel™ Impact Driver.

Shortly before the parts were finished, a pair of uprights was found, allowing me to mount at least the center section and get an idea of how the Color Wall would go together. That’s when I discovered that this iteration of Madix units has the shelves tipping back considerably, meaning that my entire fascia would be badly out of plumb. A handful of shims under the plywood deck put things back to rights. This also gave me the opportunity to see how the lights would illuminate the Color Wall area so I set up some “merchandise” to have a look.

Shortly before the parts were finished, a pair of uprights was found, allowing me to mount at least the center section and get an idea of how the Color Wall would go together. That’s when I discovered that this iteration of Madix units has the shelves tipping back considerably, meaning that my entire fascia would be badly out of plumb. A handful of shims under the plywood deck put things back to rights. This also gave me the opportunity to see how the lights would illuminate the Color Wall area so I set up some “merchandise” to have a look.

Given that the shop and the store are separated by Nantucket Sound, the installation phase involved a number of trips on the company aircraft, certainly a change in my routine! The parts were sent over earlier by freight boat.

Given that the shop and the store are separated by Nantucket Sound, the installation phase involved a number of trips on the company aircraft, certainly a change in my routine! The parts were sent over earlier by freight boat.

After the tops were installed and the pegboard inhaled its “Elephant’s Breath”, the beadboard backing for the Color Wall was applied. Next were the sides and the puck lights, then the rest of the shelves. It got interesting here because the existing units were not plumb, not level and not in one plane. I may be the only one who notices, but it did throw things a tad out of whack.

After the tops were installed and the pegboard inhaled its “Elephant’s Breath”, the beadboard backing for the Color Wall was applied. Next were the sides and the puck lights, then the rest of the shelves. It got interesting here because the existing units were not plumb, not level and not in one plane. I may be the only one who notices, but it did throw things a tad out of whack.

Finally ready! Although the building and installing of the display was finished, the job wasn’t over. The two pallets of paints, brushes, rollers, brochures and sample pots were delivered in, shall we say, a random order. It took hours to separate the three different finishes of each color and the six different primers. It was well worth it, though. These are absolutely top-drawer paints and papers.

Finally ready! Although the building and installing of the display was finished, the job wasn’t over. The two pallets of paints, brushes, rollers, brochures and sample pots were delivered in, shall we say, a random order. It took hours to separate the three different finishes of each color and the six different primers. It was well worth it, though. These are absolutely top-drawer paints and papers.

Done and done! The Farrow&Ball paints and wallpapers can be seen in Anchor Ace Hardware at 267 Cotuit Road, Sandwich, Massachusetts, or at Marine Home Center, 134 Orange Street, Nantucket, Massachusetts.

-dvl

Leave A Comment